Thermal Transfer vs Direct Thermal Label Printing

Thermal Transfer-Direct Thermal Label Printing-Ribbons-Barcode Printer-Barcode Scanner

While picking the correct barcode label, you'll have to begin by choosing whether to utilize thermal transfer and direct thermal printing. It's the mix of this printing strategy with the correct label materials and ribbon that at last decides the correct decision for a specific application.

This is what each printing sort means and how it sets with the correct barcode labels for explicit applications and conditions.

DIRECT THERMAL PRINTING

Direct thermal printing doesn't utilize ink, toner, or strip; rather, it takes a picture straightforwardly on printed material. Direct thermal materials offer a shorter life than thermal move and may blur after some time. They're usable for essential labeling applications, for example, shipping labels, where labels just need transient sturdiness and readability. Be that as it may, if your labels will be presented to outrageous temperatures, light, scraped area, or synthetic substances, or in the event that you'll require them to a year ago or progressively, direct thermal is definitely not a decent choice.

THERMAL TRANSFER PRINTING

For more label toughness, particularly for protection from outrageous temperatures, daylight, scraped spot or synthetic compounds, thermal move printing is the best approach. Thermal move utilizes a strip to print a solid, enduring picture on a label. A thermal printhead applies thermalth to the ribbon, which melts ink onto the material to frame the picture. This system gives unrivaled picture quality and solidness on request. To guarantee the privilege natural and application obstruction, the label material and ribbon must be painstakingly coordinated.

THERMAL TRANSFER RIBBONS

Thermal move strips are accessible in an assortment of types for a wide scope of labeling applications:

Wax Ribbons are utilized when there is next to zero introduction to frail synthetic compounds as well as moderate scraped area.

Wax/Resin Ribbons are for outrageous concoction introduction and additionally presentation to direct scraped area, or where UL/cUL endorsement is required.

Tar Ribbons are utilized for brutal to extraordinary compound introduction as well as presentation to unnecessary scraped spot, and where UL/cUL endorsement is required.

KEY CONSIDERATIONS FOR CHOOSING LABELS

SURFACE

Diverse label materials and glues are required for attachment to exceptional shapes, for example, bended surfaces.

TEMPARATURE

Direct thermal materials by and large perform well at application temperatures of in any event 25°F and administration temperatures of - 65°F to 200°F. Labeling outside this range requires thermal move and normally a claim to fame cement.

Scraped spot

A ribbon with higher pitch substance will give improved protection from scouring and scratching of your labels.

Utensil USAGE

When utilizing a label utensil, the label must be cut contrastingly so it strips off appropriately from the liner. Apertures aren't prescribed on the grounds that they change label solidness and make it hard to discharge from the liner.

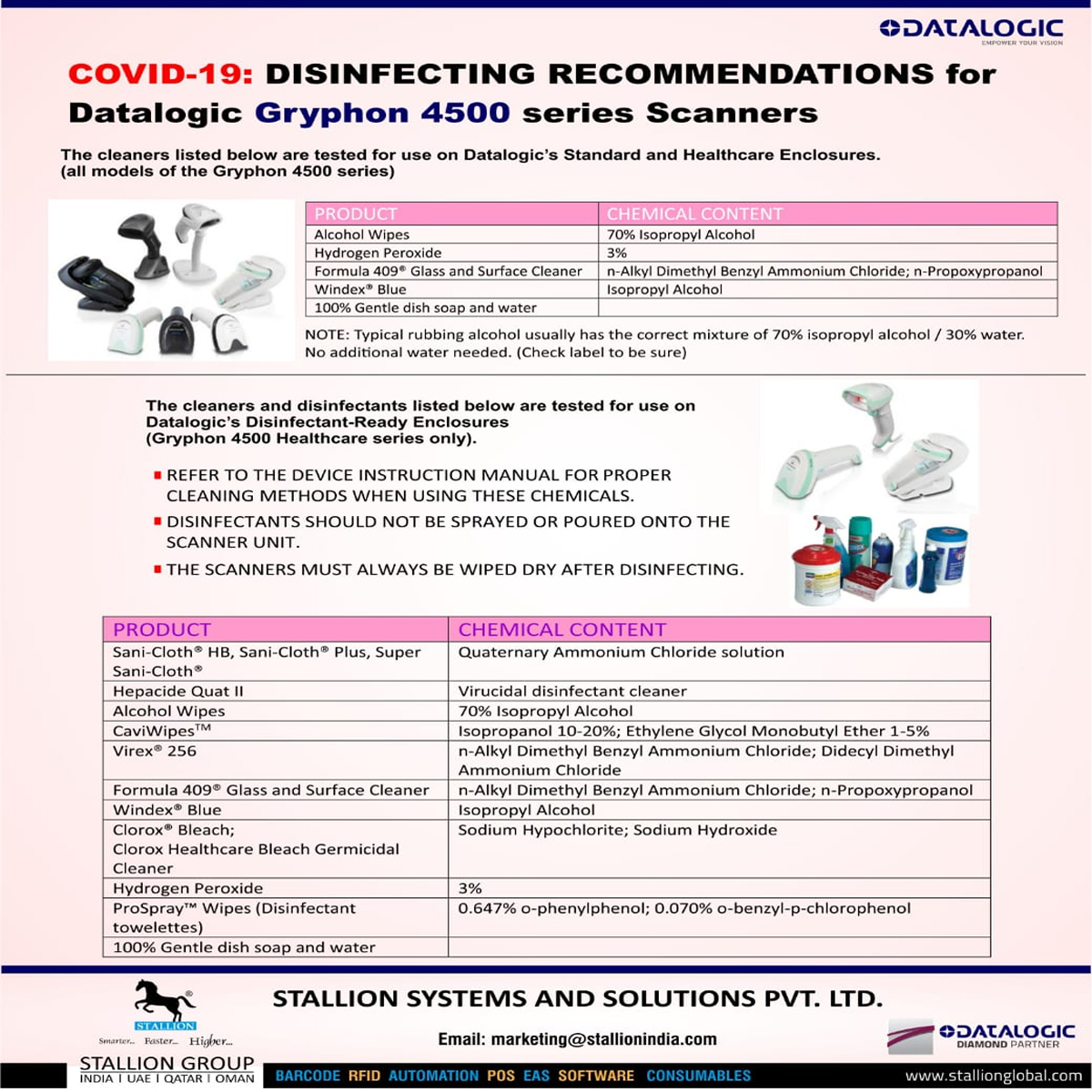

Substance RESISTANCE

A thermal move label is required if your label will be presented to direct to extraordinary synthetics. A high-sturdiness pitch strip is additionally prescribed on the off chance that you need protection from brutal or outrageous synthetic concoctions.

INDOOR/OUTDOOR USE

A thermal move manufactured material is ideal for open air conditions, for example, sun, downpour, and day off.

PRINT SPEED, DARKNESS, AND DOTS PER INCH (DPI)

Material and ribbon determination impact greatest print speed, and certain print speeds, printing necessities, and strips require higher print murkiness and additionally a higher DPI. Exceptional materials, for example, synthetics, may likewise be required to guarantee legitimate printing.