Datalogic MEMOR10-Handheld Mobile Computer

Datalogic MEMOR™ 10-Handheld Mobile Computer

♦ The superior performance of this Android™ full touch PDA is able to support a multitude of applications in various environments, including a new model with a 2D Megapixel scan engine option for improved performance. The MP scan engine also enables DotCode (tobacco tracking) and Digimarc® watermarking reading.

" The Memor 10 PDA brings the power and performance of a smartphone with the user-friendly experience of Android in a slim and compact device with an integrated 2D imager. It also incorporates Datalogic’s industry-first wireless charging system for ultra-reliable contactless charging, paired with a 1-piece swappable battery for the best operating advantage."

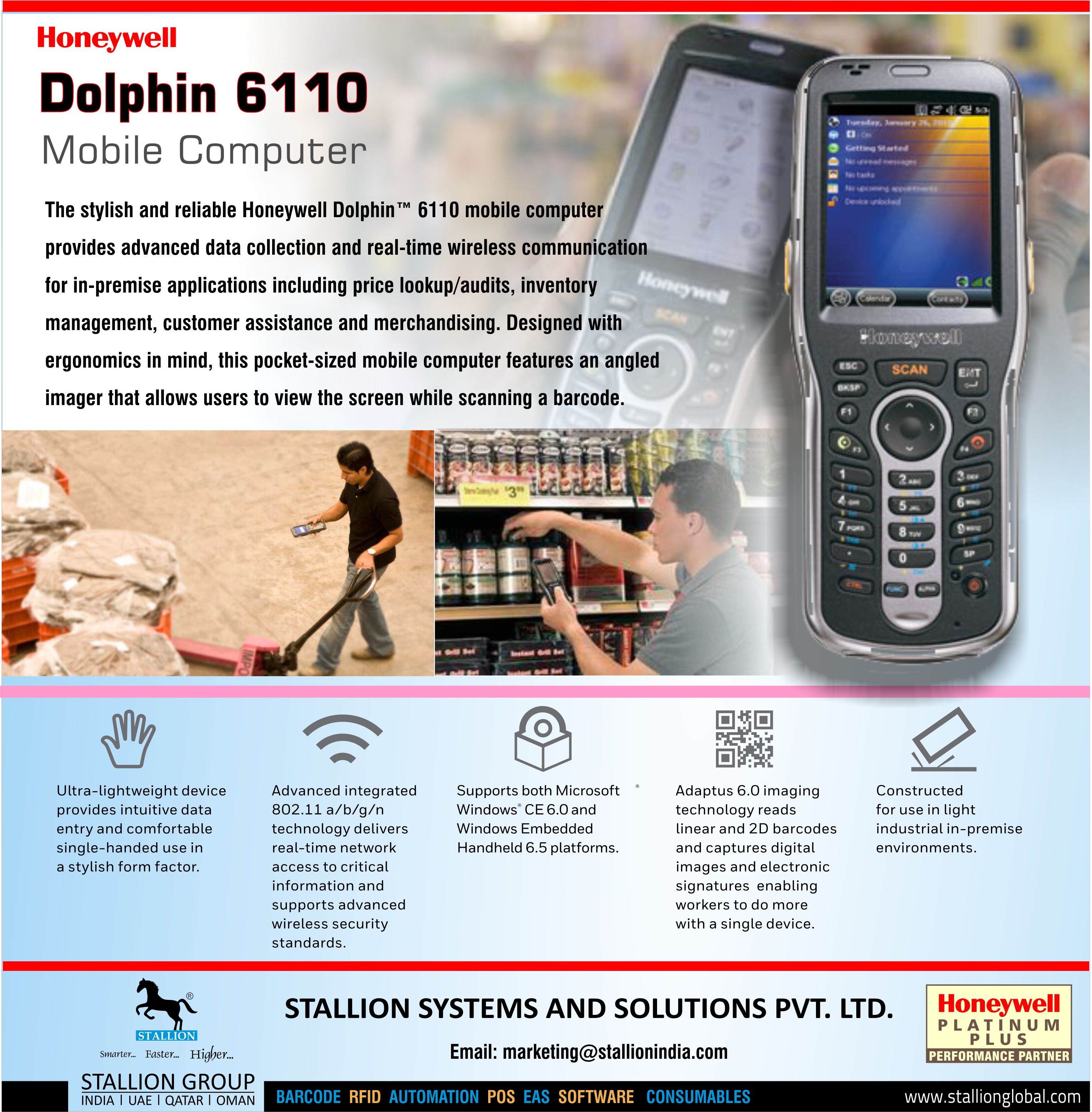

♦ Ultra-Ergonomic, compact and robust

♦ 5 inch capacitive multi-touch HD display

♦ Android 8.1 (Oreo) with Google Mobile Services

♦ Wireless charging

♦ Dual-band Wi-Fi

♦ Featuring LTE-Advanced/4G+

♦ Assisted GPS for location-based apps

♦ NFC for proximity communications

♦ Datalogic's patented 'Green Spot technology for visual good-read feedback

♦ Chemical resistant plastics/enclosure

♦ The Memor 10 PDA also includes a state-of-the-art octa-core platform, featuring Android 8.1 (Oreo) with Google Mobile Services. These specs led to the endorsement by Google, who validated the Memor 10 PDA as one of the first mobile computers to join their ‘Android Enterprise Recommended’ program for rugged devices!

♦ The Memor 10 PDA is also available in a Healthcare version which includes the same features with a cleanable enclosure and dedicated accessories.

♦ Stallion Group is the Authorized Distributor and Diamond Partner for Datalogic in India and the Middle East.

♦ Our full range of Barcode Scanner products includes Fixed Retail Scanners, Hand Held Scanners, Mobile Computers, Sensors, Laser Marking Systems, Safety, Vision Systems, Stationary Industrial Scanners, RFID Systems and OEM Barcode Readers.

We provide a unique portfolio of smart, interconnected devices able to protect, identify, sense, check and mark. We‘re focused on Automotive, Electronics, Packaging and General Manufacturing customers in the Industrial Production world.

INTRALOGISTICS

♦ Cold Storage Datalogic scanning solutions working in frozen environments provide full traceability along the entire supply chain.

♦ Forklift Solution Far distance 1D and 2D barcode scanning is enabled by PowerScan™ AR handheld readers. Combined with the SD9030 dongle and Rhino II™ vehicle mount computer, it represents a complete solution for forklifts.

♦ Automated Guided Vehicles Laser scanner avoids any collision by slowing down or stopping the vehicle in the presence of operators or obstacles.

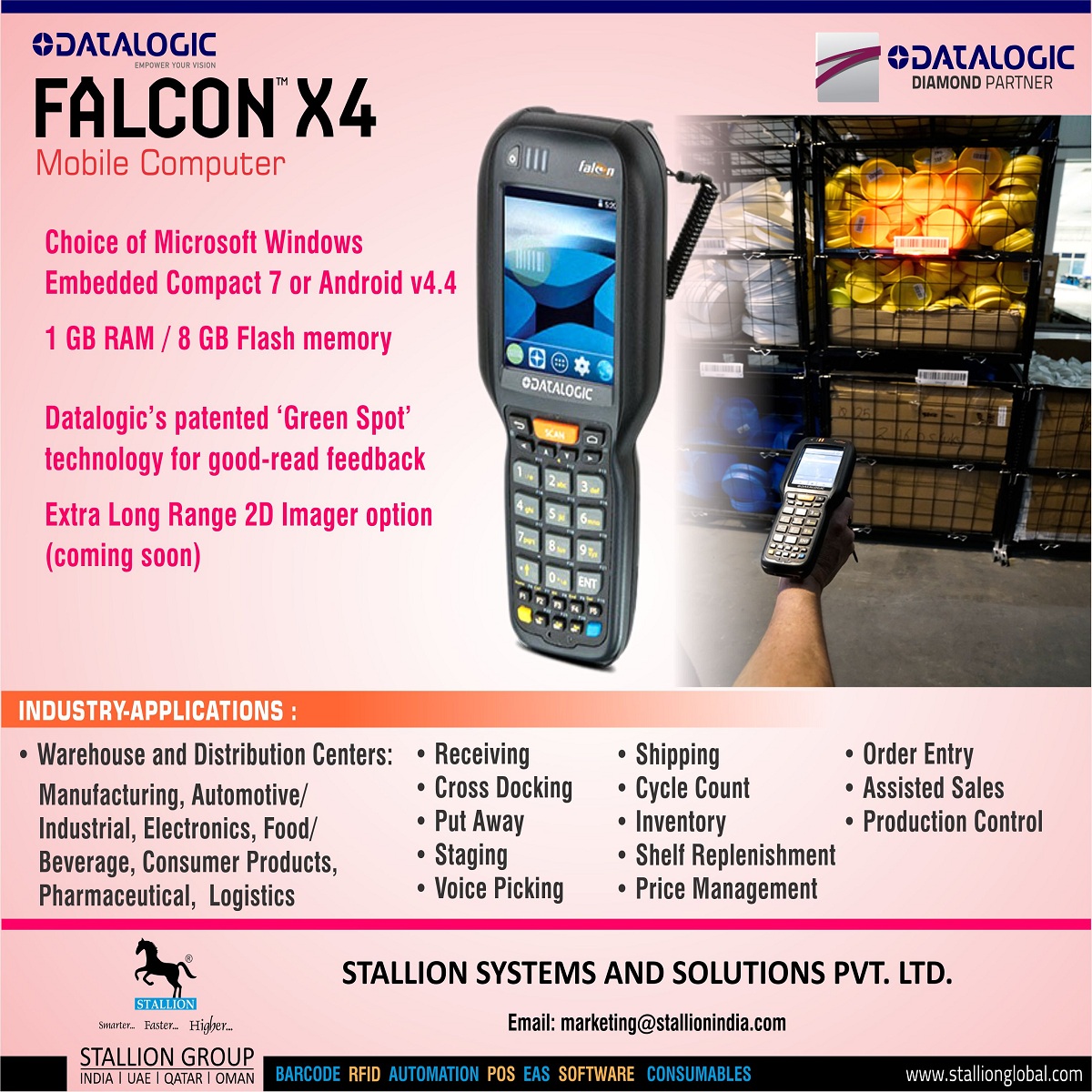

♦ Picking on production line In warehouse operations, workers have to track and report the picked parts in real-time through rugged and ergonomic mobile computers like Falcon™ X4 and Skorpio™ X4.

♦ Manual Induction Totes and packages are manually inducted into an automatic warehousing system using Datalogic industrial handheld scanners.

♦ Warehouse Management A wide array of solutions from Datalogic including handheld scanners, smart cameras, fixed readers and mobile computers deliver error-free warehouse operations processing.

ELECTRONICS

♦ DPM Code Verification Direct Part Marking (DPM) etched directly on materials are validated by Datalogic vision systems ensuring code readability and assembly traceability.

♦ Machinery Safeguarding Safety light curtains from Datalogic maximize production while protecting operators from harm.

♦ Machine Setup Handheld Datalogic scanners identify the component cartridge and the appropriate insertion location ensuring proper setup.

♦ Inspection Vision systems from Datalogic inspect position, alignment, and assembly with high-accuracy measurements.

♦ Laser Marking A wide variety of materials including plastic, aluminium, stainless steel and titanium are permanently marked by Datalogic laser marking systems.

♦ Traceability Parts and subassemblies are continuously tracked by smart cameras, vision systems and fixed readers from Datalogic throughout the production process.

PACKAGING

♦ Label Print and check Automatic application of bar code labels are verified by Datalogic ID readers and smart cameras to check data consistency and quality standards.

♦ Detection Fast machinery with limited space rely on Datalogic smart cameras and miniature sensors for small parts detection.

♦ Configuration Industrial handheld scanners from Datalogic are used to configure machines for operation by using bar codes.

♦ Safety Operator safety is guaranteed by light curtains while the access of material is allowed because of the muting function.

♦ Traceability Throughout production Datalogic fixed scanners track items to guarantee integrity, user safety, and efficient management of recalls.

♦ Verification and Inspection Labels are inspected to make sure they are in the proper position and orientation as well as including the correct bar code and information.

TIRES

♦ Sorting Area Protection The safety light curtain with integrated muting function is used to protect the sorting area. The muting function allows tires to be taken by a forklift for handling and warehousing management.

♦ Sorting Bar codes are identified to correctly direct tires to a distribution network or their final destination.

♦ Final Inspection Tires are manually identified by operators using handheld bar code readers.

♦ Final Finishing and Inspection Tires are identified and tracked as they progress through rough manufacturing and into final finishing and inspection stations.

♦ Hazardous Area Protection The Laser Sentinel protects the hazardous area in front of tire vulcanizing machines. Because of the two protective fields, the Laser Sentinel can independently manage the slow down and the stopping of the robot arm.

♦ Tire Height Measurement The height of the tire is measured to ensure the correct handling in the production processes. The DS2 Area Sensor is able to measure the height of the tire and send the data to the system.

AUTOMOTIVE

♦ Traceability Automotive parts require end-to-end traceability. Datalogic industrial handheld scanners, smart cameras and fixed readers scan parts and components during vehicle assembly.

♦ Assembly Verification Smart cameras and vision systems from Datalogic detect, inspect, and verify the component presence and position eliminating the need for manual inspection.

♦ Robot Guidance Robot and laser guidance is delivered by Datalogic machine vision systems and cameras to maximize accuracy and safety in automated production.

♦ Direct Part Marking Datalogic delivers solutions for Direct Part Marking (DPM) with laser marking systems that etch bar codes directly on parts. Vision systems, handheld and fixed scanners are used for DPM code/ text identification for verification and item traceability purposes.

♦ Robot Safety Datalogic solutions for safety deliver access control and operator protection in robotic work cells through safety light curtains.

♦ Work In Progress Work In Progress (WIP) is tracked using Datalogic fixed readers, vision systems and industrial handheld scanners along the entire production process.

INDUSTRY-APPLICATIONS:

Retail:

♦ Assisted Sales

♦ Inventory

♦ Access Control

♦ Shop Floor Applications

♦ Mobile POS

Transport & Logistics:

♦ Route Accounting

♦ Direct Store Delivery

♦ Workforce Management

Manufacturing:

♦ Production and Quality Control

♦ Intra-Logistics

♦ Inventory

♦ Field Maintenance

Healthcare:

♦ Bedside Care

♦ Pharmacy

♦ Inventory Management

♦ Labs